Future Trends in Membrane Bioreactor Technology and Its Global Impact

Future Trends in Membrane Bioreactor Technology and Its Global Impact

Blog Article

Comprehending Membrane Bioreactors: The Future of Wastewater Therapy

Membrane layer bioreactors (MBRs) represent a significant advancement in the field of wastewater therapy, incorporating biological procedures with sophisticated membrane layer filtering to enhance effluent top quality. As worldwide water scarcity and rigorous regulative frameworks come to be progressively pushing problems, MBR technology uses an effective feedback through its ability to decrease footprint and maximize resource recuperation. Nevertheless, the fostering of MBRs is not without its difficulties, which warrant careful factor to consider. What are the crucial factors affecting their implementation and long-lasting stability in numerous contexts? The responses may reshape our strategy to wastewater management.

What Are Membrane Layer Bioreactors?

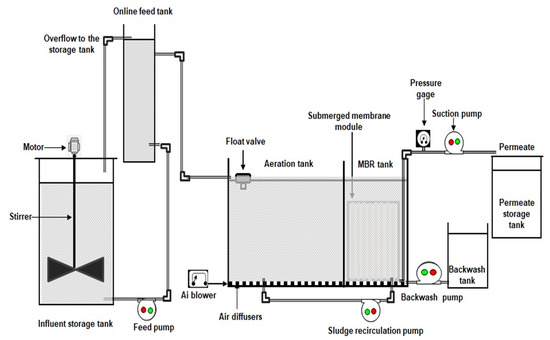

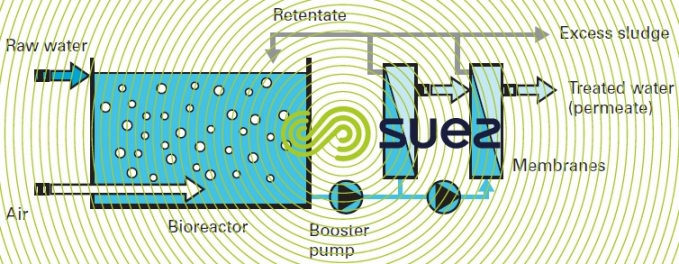

The core elements of MBR systems include a bioreactor where microbial activity happens and a membrane system that filters the blended liquor. This double performance allows the simultaneous deterioration of raw material and solid-liquid splitting up in a solitary action. MBRs can run in both submerged and outside configurations, with immersed systems being more usual as a result of their portable layout and functional effectiveness.

The adoption of MBR technology has obtained grip in different applications, varying from local wastewater therapy to industrial effluent management. MBRs are specifically useful in circumstances where area is restricted or stringent effluent top quality requirements need to be met. By maintaining a high focus of bacteria within the bioreactor, MBRs enhance the destruction of natural pollutants, therefore generating higher treatment performances compared to traditional techniques.

Key Benefits of MBR Modern Technology

The combination of organic treatment with membrane layer filtering in MBR systems provides countless advantages that establish it apart from standard wastewater treatment techniques. Among the primary advantages is the boosted effluent high quality. MBRs efficiently remove put on hold microorganisms and solids, attaining higher levels of filtration that fulfill strict discharge requirements and facilitate water reuse applications.

An additional significant advantage is the minimized sludge manufacturing. MBR systems generate less excess sludge, causing reduced disposal prices and a decrease in environmental effect. The shut nature of the membrane layer system minimizes the risk of odor discharges and boosts total procedure control.

Lastly, MBRs are adaptable and flexible, making them ideal for numerous wastewater kinds, consisting of industrial and municipal sources. The ability to integrate with sophisticated treatment innovations additionally improves their efficiency, making MBRs an appealing option for the future of wastewater monitoring.

Obstacles and Limitations of MBRs

While MBR modern technology supplies countless benefits, it additionally encounters numerous obstacles and restrictions that can affect its extensive adoption. One significant challenge is the high capital and functional prices connected with MBR systems. The preliminary investment for membrane materials and the essential framework can be considerable, making it less available for smaller districts or sectors.

Additionally, membrane layer fouling stays a vital problem that can decrease system efficiency and increase upkeep needs. Fouling occurs when solids, raw material, or microorganisms accumulate on the membrane layer surface, leading to minimized permeability and calling for regular cleaning or substitute.

One more limitation entails the complexity of the modern technology. MBR systems need experienced employees for operation and upkeep, which can be a barrier in areas with minimal technical experience. Additionally, the disposal of invested membranes presents ecological issues, as the materials are frequently not naturally degradable and can contribute to lose management obstacles.

Finally, while MBRs can click to investigate properly treat a vast array of wastewater, they might not appropriate for all applications, particularly those with high concentrations of fats, oils, and oils, necessitating additional research study and technology to deal with these restrictions.

Applications of Membrane Layer Bioreactors

In numerous industries, membrane bioreactors (MBRs) have actually emerged as a flexible option for wastewater therapy (Membrane Bioreactor). Their applications extend municipal, industrial, and agricultural setups, showcasing their flexibility and performance in varied environments. In community wastewater treatment plants, MBRs substantially boost effluent top quality, allowing for water reuse and decreasing the environmental effect of released wastewater

Industrially, MBRs are utilized in food and drink handling, fabric production, and pharmaceutical manufacturing, where they successfully deal with high-strength waste streams. Their ability to manage differing and rising and fall lots impurity focus makes them specifically useful in these fields. In addition, MBRs assist in the elimination of microorganisms, suspended solids, and organic issue, adding to conformity with strict discharge guidelines.

In farming, MBRs are progressively used for treating farming drainage and livestock wastewater, allowing the recovery of nutrients for plant food manufacturing. They likewise aid in the therapy of greywater for watering, promoting sustainable water monitoring techniques.

The adaptability of MBRs is additional evidenced by their assimilation with various other innovations, such as anaerobic digestion and progressed oxidation processes, enhancing total performance and resource recuperation in wastewater treatment systems.

The Future of Wastewater Therapy

Improvements in innovation and a growing emphasis on sustainability are shaping the future of wastewater therapy. Membrane bioreactors (MBRs) exhibit this shift by incorporating biological therapy processes with membrane filtering, resulting in high-grade effluent appropriate for reuse. The trend in the direction of round economies is prompting centers to take on MBRs for their ability to recuperate sources, such as water and nutrients, from wastewater.

Advancements in membrane layer materials and configuration are enhancing the performance and durability of MBR systems, lowering operational prices and energy intake. Smart technology combination, consisting of real-time tracking and automated control systems, is more optimizing efficiency and making it possible for predictive upkeep, thus reducing downtime.

Furthermore, governing pressures and societal assumptions Visit Website are pushing towns and sectors to embrace even more lasting practices. Membrane Bioreactor. The shift in the direction of decentralized wastewater treatment services is obtaining grip, enabling localized treatment that minimizes transport costs and energy use

Final Thought

Membrane layer bioreactors (MBRs) stand for a transformative strategy to wastewater treatment, integrating biological procedures with innovative membrane layer technology. The advantages of MBRs, including enhanced effluent high quality, minimized spatial demands, and reduced sludge manufacturing, place them as a sensible remedy amid growing urbanization and more stringent ecological policies. In spite of existing difficulties, the continued development in membrane materials and operational techniques promises to reinforce the efficacy and adoption of MBRs, ensuring their crucial duty in the future of lasting wastewater monitoring.

Membrane layer bioreactors (MBRs) stand for a significant advancement in the area of wastewater treatment, integrating biological procedures with sophisticated membrane layer filtering to improve effluent quality.Membrane bioreactors (MBRs) incorporate organic therapy processes with membrane filtering to efficiently treat wastewater.The assimilation of organic treatment with membrane layer purification in MBR systems uses various benefits that establish it apart from conventional wastewater treatment approaches. Membrane bioreactors (MBRs) exhibit this change by integrating biological therapy processes with membrane layer filtering, resulting in premium effluent visit the site suitable for reuse.Membrane layer bioreactors (MBRs) represent a transformative strategy to wastewater therapy, integrating organic processes with innovative membrane technology.

Report this page